Live Chat Support

We support reliability testing in accordance with domestic

and international standards for the automotive field.

ATL values our customers' business and

provides the highest quality and technical services.

Testing History

-

- ·Ambient Light

- ·AVN

- ·Audio

- ·AFLS

- ·SBCM

- ·Side Mirror Camera

- ·BMS(Battery Management System)

- ·Electric-Vehicle Battery

-

- ·ECU(Engine Control Unit)

- ·PAS

- ·SAS

- ·AAF

- ·RWS

- ·MDPS

- ·Immobilizer

- ·Head Lamp

-

- ·Rear Combi Lamp

- ·Center Lamp

- ·Side Marker

- ·CHMSL

- ·Fog Lamp

- ·Emblem

- ·Navigation

Support Services

-

Standard Review

-

Reliability Testing

-

Defect Analysis

-

Failure Analysis

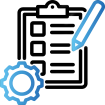

Electronics Testing Services

Automotive TEST

Hyundai & Kia Motors ES SPEC

(Electronic Component Environmental Testing)

-

- Electrical Performance Testing

- Operating voltage, Dark current, Power reverse polarity test, Overvoltage test

- Power voltage fluctuation test during startup

- Power voltage fluctuation test during electrical load operation

- Power voltage momentary interruption test, Short circuit test

- Power voltage interruption test, Battery charge/discharge test

- Transient voltage test,

- Electromagnetic immunity test (outsourced)

-

- General Environmental Testing

- High temperature storage/operation test, Low temperature storage/operation test

- High temperature and humidity test with power application

- Temperature and humidity cycle test, Temperature cycle test

- Shock resistance test, Drop test, Condensation test

- Temperature characteristic test, Liquid resistance test, Water resistance test (outsourced), Salt spray test (outsourced), Ozone resistance test (outsourced)

-

- Vibration Durability Testing

- Resonance point durability test

- Vibration durability test 1

- Vibration durability test 2

-

- Limit Testing

- High/Low temperature operation limit test

- High/Low voltage operation limit test

-

- Environmental Durability Testing

- Thermal shock durability test

- High temperature operation durability test

- Shock durability test

- Button operation durability test

(Lead-free Soldering Testing)

-

- Reliability Testing

- Thermal shock durability test

- Power-applied temperature cycle test

- Vibration durability test

- High temperature and humidity durability test

-

- Reliability Inspection

- Whisker inspection (outsourced)

- Cross-section inspection

- Bonding strength inspection (outsourced)

-

(Soldering Testing)

- Chip component test

- Gull Wing component test

- Soldering defect test

-

(Component Delamination Testing)

- PCB external/internal requirements

- Thermal Stress test

- Soldering test

- High voltage test

- High temperature storage durability test

- Thermal shock durability test

- High temperature and humidity durability test

-

(Highly Accelerated Life Testing)

- Low temperature step stress test

- High temperature step stress test

- Vibration step stress test

- Rapid temperature change test

- Combined stress test

- Structural analysis

(General Motors) 3172

- Electrical

- Parasitic Current

- Power Supply Interruptions

- Battery Voltage Dropout

- Sinusoidal Superimposed Voltage

- Pulse Superimposed Voltage

- Intermittent Short Circuit to Battery and to Ground

- Continuous Short Circuit to Battery and to Ground

- Ground Interconnect Shot to Battery

- Open Circuit – Single Line Interruption

- Open Circuit – Multiple Line Interruption

- Ground Offset / Power Offset

- Discrete Digital Input Threshold Voltage

- Over Load – All Circuits

- Over Load – Fuse Protected Circuits

- Isolation Resistance

- Crank Pulse Capability and Durability

- Mechanical

- Vibration with Thermal Cycling

- Post Thermal Fatigue Vibration

- Mechanical Shock – Pothole

- Mechanical Shock – Collision

- Mechanical Shock – Closure Slam

- Crush For Housing – Elbow Load

- Crush For Housing – Foot Load

- Connector Installation Abuse – Side Force

- Connector Installation Abuse – Foot Load

- Free Fall

- Fretting Corrosion Degradation

- Enclosure

- Dust(outsourced evaluation) , Water(outsourced evaluation)

- Seal(outsourced evaluation), Water Freeze(outsourced evaluation)

- Sugar Water Function impairment(outsourced evaluation)

- Climatic

- High Temperature Degradation

- Thermal Shock Air To Air (TS)

- Power Temperature Cycle(PTC)

- Humid Heat Cyclic(HHC)

- Humid Heat Constant(HHCO)

- Salt Mist

- Salt Spray

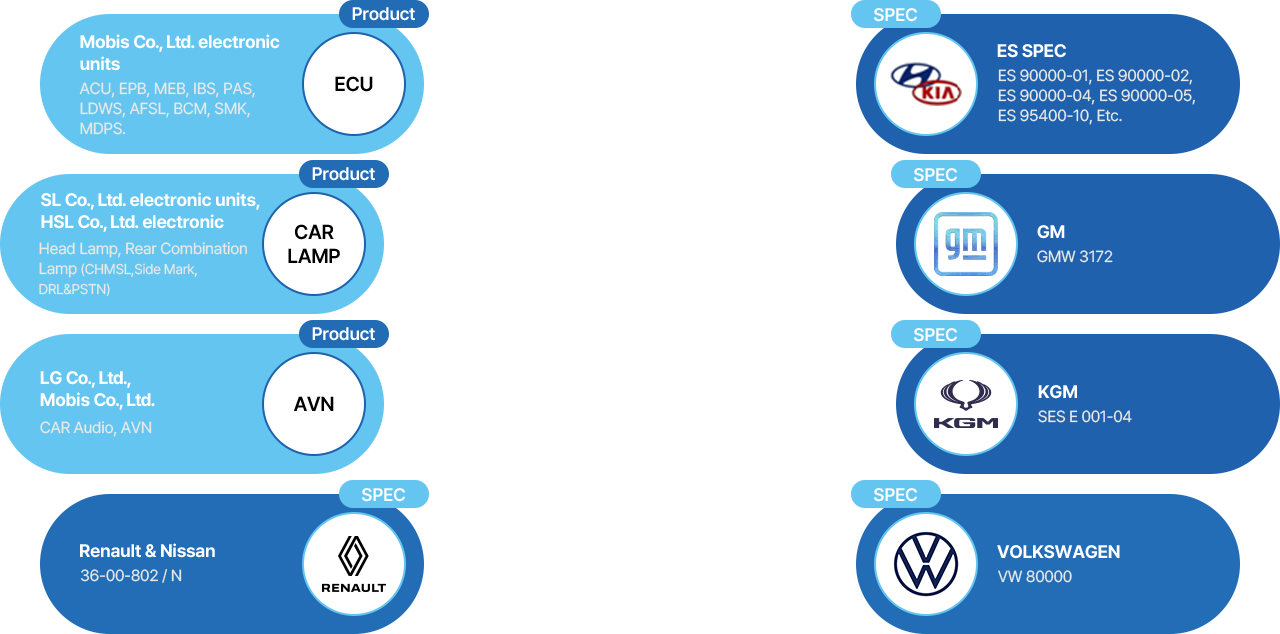

Electrical Performance Tester

- EMTESTER

- Manufacturer : EMTEST

- Configuration : Arbitrary Generator

- Equipment specifications : 4 CH / Frequency, 10 V unipolar DC 50 ㎑

- Configuration : Voltage Drop Simulator

- Equipment specifications : 60 V / 50 A

- Testable Items

- -ES95400-10 (Rev. 21) All items supported

- -6.1.6 Power voltage fluctuation test during electrical load operation

- -6.1.7 Power voltage momentary interruption test

- -6.1.9 Power voltage interruption test

- -6.1.12 Reset ripple combined test

- -GMW3172 (2018) All items supported

- -GMW3172 (2018) 9.2.18 Switched Battery Lines

- -GMW3172 (2018) 9.2.19 Battery Line Transients

- Bi-Polar DC Power Supply

- Manufacturer : KIKUSUI

- Configuration : PBZ 20-20

- Equipment specifications : 20 V, 20 A

- Configuration : PBZ 40-10

- Equipment specifications : 40 V, 10 A

Analysis Equipment

- Scanning Electron Microscope (SEM)

- Magnification : 30 ~ 250,000x

- Resolution : 5 nm

- Detector : Secondary Electron (SEI), Back Scattered Electron (BSE)

- SDD Detector : Energy Dispersive X-ray Spectrometer (EDS)

- Ion Sputter Coater

- - Pretreatment equipment that coats Au/Pt thin film

- Polishing Machine

- Specimen Preparation Machine (Cutting Machine)

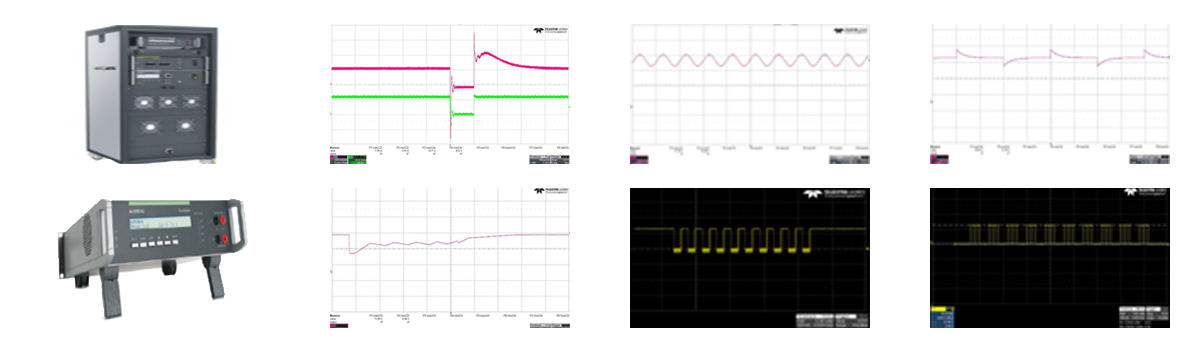

Thermal Shock Chamber (Large Capacity)

- Thermal Shock Chamber (Large Capacity)

- Manufacturer : ESPEC, HITACHI

- Model : ES-306L, TSA-301L-W

- Temperature range : (-65 ~ 200) °C

- Method : Damper method

- Internal dimensions : 970 * 460 * 670 (300 Liter)

Thermal Shock Chamber

- Thermal Shock Chamber

- Manufacturer : ESPEC, ENEX SCIENCE

- Model : EN-DT3-500, TSA-71L-A, TSA-71L-W

- Temperature range : (-65 ~ 200) °C

- Method : Damper method

- Internal dimensions : 500 * 500 * 400 (100 Liter)

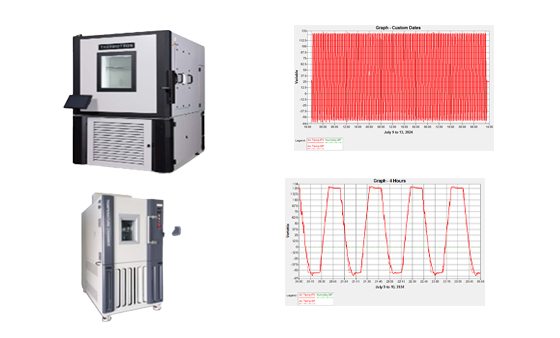

PTC

- Power Temperature Cycle Chamber

- Manufacturer : ENEX SCIENCE, THERMOTRON

- Model : EN-FTC-700, SE-600-3-3, SE-1200-15-15

- Temperature range : (-65 ~ 200) °C

- Temperature change rate : 7, 10, 15 ℃/min

- Internal dimensions : (300 Liter) 1 020 * 1 000 * 1 170 (1184 Liter)

Temperature and Humidity Chamber

- Temperature and Humidity Chamber

- Manufacturer : ESPEC, ENEX SCIENCE, GTPS, NEURONFIT

- Temperature range : (-60 ~ 150) °C

- Humidity range : (20 ~ 98) R.H.

- Internal dimensions : 1000 * 1000 * 1000 (1000 Liter)

Combined Vibration Tester (6.5 ton)

- Combined Vibration Tester (6.5 ton)

- Manufacturer : uzhou sushi testing group

- Model : DC-6500-65

- Max Force : 63.6 kN

- Max Payload : 1000 kg

- Max Accel : 980 m/s2

- Frequency Rage : 2 ~ 2700 Hz

- Temperature range : (-40 ~ 150) ℃

- Humidity range : (20 ~ 98) % R.H.

Combined Vibration Tester (4 ton)

- Combined Vibration Tester (4 ton)

- Manufacturer : ETS Solution

- Model : IPA-60L/M437A/GT800M

- Max Force : 40.0 kN

- Max Payload : 500 kg

- Max Accel : 980 m/s2

- Frequency Rage : 5 ~ 2 700 Hz

- Temperature range : (-40 ~ 150) ℃

- Humidity range : (20 ~ 98) % R.H.