Live Chat Support

1. Main Services

Microstructure analysis of materials / Metal structure analysis (grain size, pores) / Specific area cross-section analysis / Mineral analysis / Appearance evaluation

- Scanning Electron Microscope (SEM)

- Magnification : 30 ~ 250,000x

- Resolution : 5 nm

- Detector : Secondary Electron (SEI), Back Scattered Electron (BSE)

- SDD Detector : Energy Dispersive X-ray Spectrometer (EDS)

- Ion Sputter Coater

- - Pretreatment equipment that coats Au/Pt thin film

2. Main Services

- Surface analysis, composition analysis, structure analysis, failure/defect analysis, and interpretation

- Reliability test analysis (automotive electronic component quality evaluation, electronic parts, and mechanical parts)

- Sample cutting, mounting, and polishing

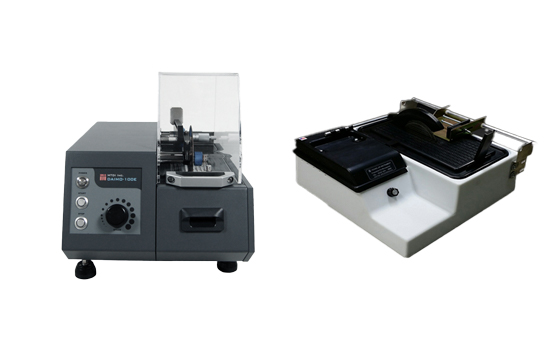

- Cutting Machine

- - Cutting blade thicknes: 0.2 ~ 0.3 inch

- - 0.5 t 이상의 PCB 보드나 작은 크기의 경도가 강한 소재의 절단

- - RPM: 0 ~ 1200

- Automatic Polisher

- - RPM: 50 ~ 500

- - Head RPM: 0 ~ 150

- Manual Polisher

- - RPM: 50 ~ 800

- - Disk Paper: #120, #400, #600, #800, #1200, #2000, #2400, #3200, #4000

- - Fine Polishing: 1 nm, 3 nm, 6nm

3. Main Services

Appearance evaluation, solder crack, damage, and dimension measurement

- Optical microscope, stereomicroscope, electron microscope

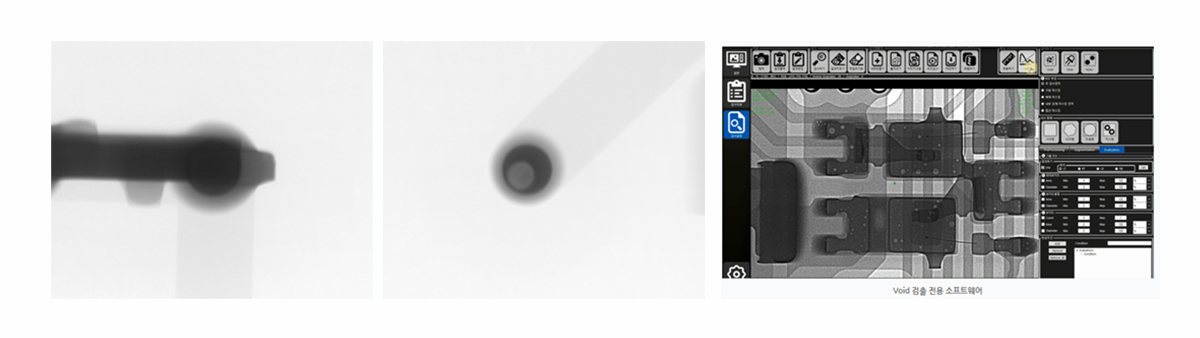

4. X-ray

- X-Ray Analysis Overview

- X-ray analysis is a key quality evaluation technique that can inspect a product's internal structure, defects, foreign materials, cracks, and solder defects in a non-destructive manner.

- Analysis Purposes

- 1. Verification of internal conditions of solder areas such as BGA, CSP, and QFN

- 2. Void analysis and solder defect detection

- 3. Evaluation of cracks, foreign matter, and bonding conditions

- 4. Inspection of mechanical part fastening status and internal structure

- 5. Verification of short circuits/disconnections inside PCBs and electronic components

- Application Targets

- - Semiconductor packages (BGA, QFN, SOP, etc.)

- - SMT components

- - Automotive electronic modules

- - Industrial sensors/connectors

- - Metal fastening components

- - Secondary battery cells, tab welding parts, etc.